SOFTWARE FOR

SUPPORT-FREE

ADDITIVE MANUFACTURING ON YOUR 3D-PRINTER

SOFTWARE FOR

COST-EFFECTIVE

ADDITIVE MANUFACTURING ON YOUR 3D-PRINTER

GENESIS Innovative

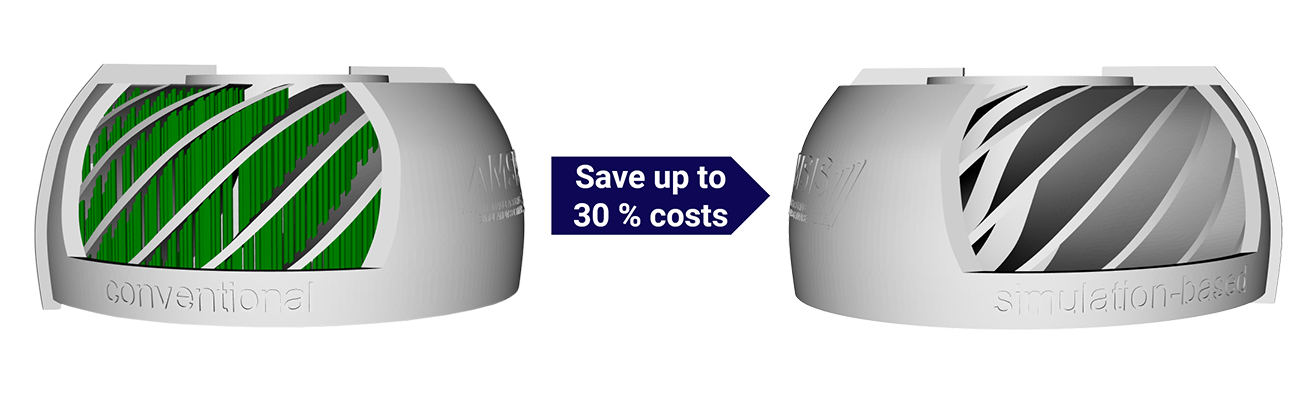

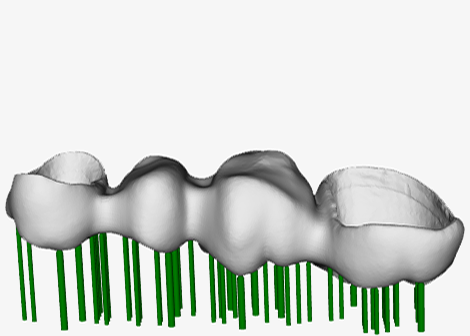

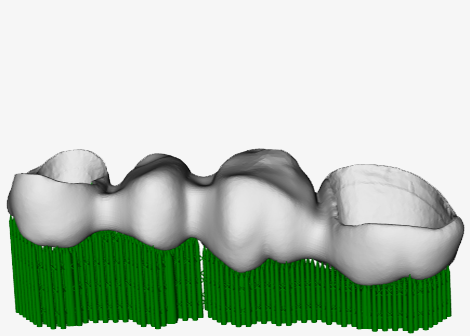

The use of software GENESIS for data preparation allows you to avoid the support structures in the range from 45° down to 20° and therefore to minimize the total support volume. For the overhangs in the range between 0° and 20° the application of support structures is still unavoidable.

AFTER

AFTER

BEFORE

BEFORE

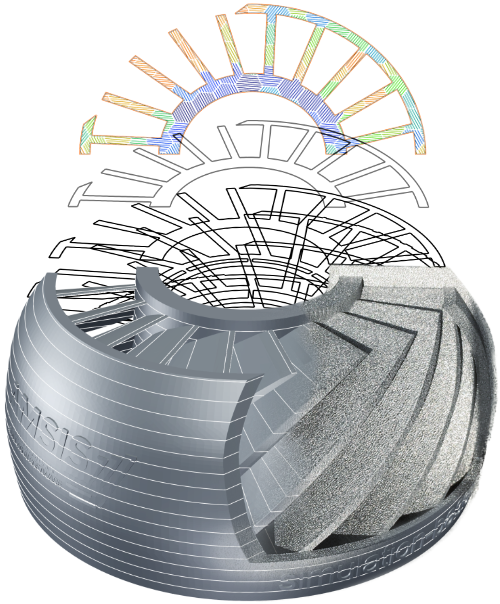

FROM DESIGN TO MANUFACTURING

Use GENESIS to prepare parts for printing

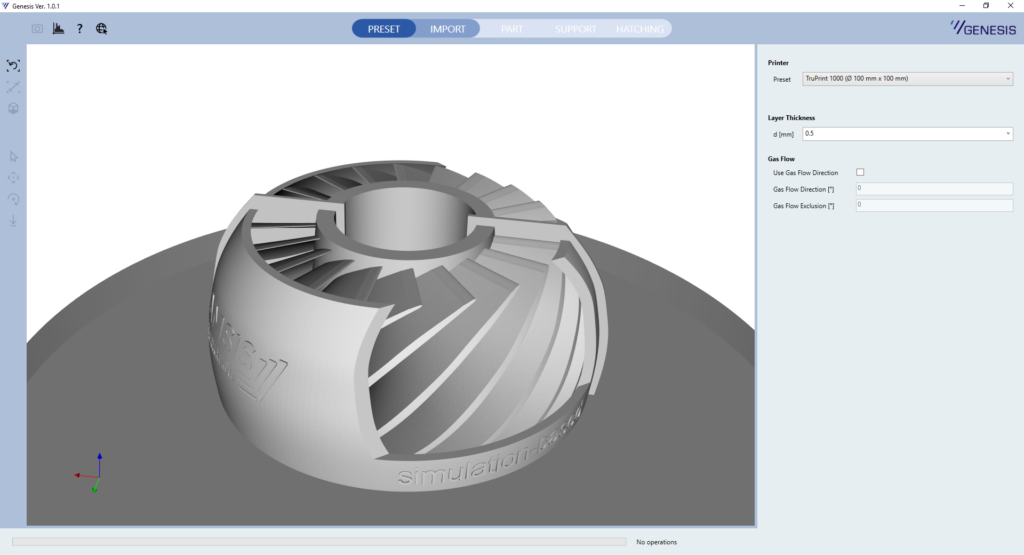

GENESIS is a knowledge-based data preparation software for additive manufacturing. The software performs the following data preparation steps:

- Import of CAD-data of the printed part (in STL-format)

- Generation of light-weight support structure

- Slicing of part and support structure

- Hatching of part and support structure (simulation-based tailored hatching strategies as well as conventional hatching strategies)

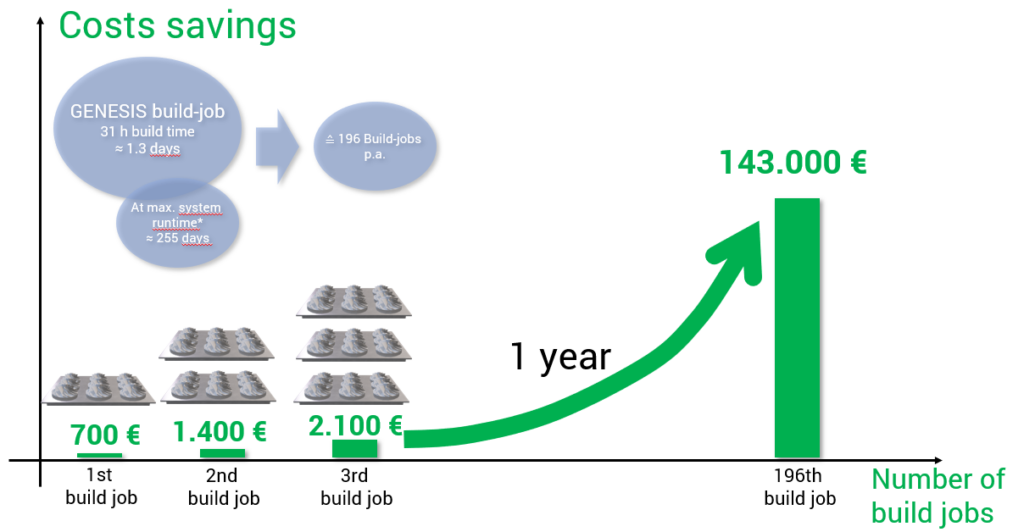

- Calculation of total manufacturing costs for the printed part

- Export of slicing and hatching data for the printing process

The software generates the simulation-based hatching strategies which are tailored for each layer of the manufactured part with an account of local geometrical particularities, especially overhangs. Using the tailored hatching strategies, you will be able to reduce support structures in the range from 45° down to 20°.

What our customers say about

Head of Testing Facilities

Senior Expert Additive Manufacturing